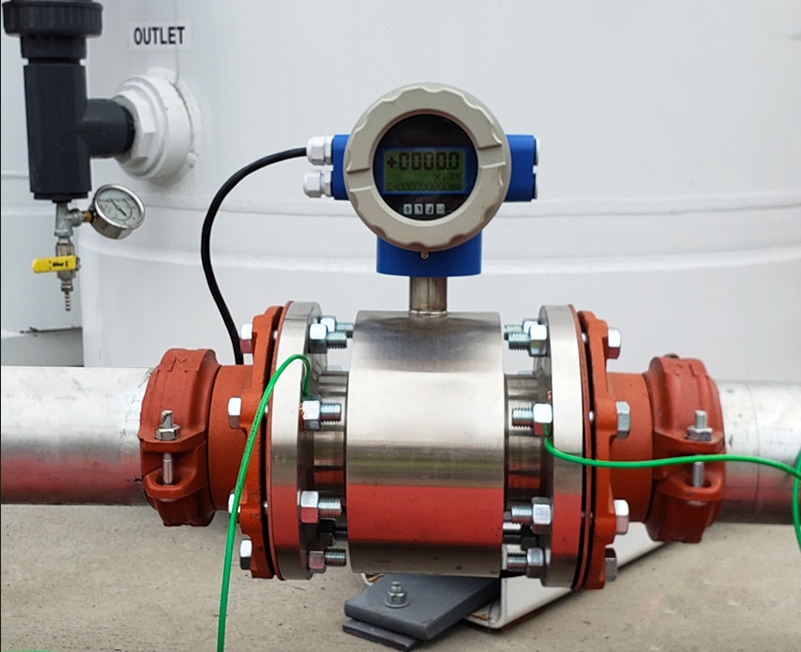

Industrial Electromagnetic Water Flow Meter Installation In USA

Industrial electromagnetic water flow meter installation in USA

Electromagnetic flow meter is developed based on Faraday's law of electromagnetic induction and is used to measure the volumetric flow rate of conductive fluids. Due to its unique characteristics, it has been widely used in the measurement of various conductive liquids in industry. Mainly used in industries such as chemical, papermaking, food, textile, metallurgy, environmental protection, and water supply and drainage, it can achieve system control when paired with computers.

Electromagnetic flow meters are divided into two display modes: split type electromagnetic flow meters and integrated type electromagnetic flow meters. Series nominal diameter DN15~DN3000.

Features:

1. There is no movable parts in the electromagnetic flowmeter, no loss pressure, simple structure, woke reliable;

2. The measurement accuracy is not affected by the change of the measured medium’s pressure, density (including liquid-solid two-phase),temperature, viscosity and other physical parameter;

3. Moisture proof and waterproof performance is good. Suit for setting up and being used underground or wet environments;

4. Compare with other flowmeter, its advantage: big measurement range , low demand in straight pipe, high accuracy;

5. Low power consumption, one set flowmeter power consumption less than 20W.

The main technical indicators:

Nominal diameter: DN15~DN3000

Accuracy: ±0.2%, ±0.3%, ±0.5%

Measurement range (flow rate): 0.01m/s~15m/s

Conductivity of medium: more than 5μS/cm

Nominal pressure: 0.6MPa, 1.0MPa, 4.0MPa

Protection grade: IP65, IP67, IP68

Electrode material: Stainless steel 316L, Hastelloy B, Hastelloy C, Titanium alloy, Tantalum alloy, Platinum-iridium alloy, Stainless steel-coated tungsten carbide and other special material .

Lining material: Neoprene,Polyurethane rubber, natural rubber, nitrile rubber, Teflon (PFA), Polytetrafluoroethylene (PTFE), fluorinated ethylene propylene (FEP OR F46), ceramics.

Connection: Flange connection [GB/T9119-2010 standard]

Ambient temperature: -10℃~50℃

Power supply: AC220V/DC24V/DC3.6V

Signal output: Analog 4mA-20mA, 0Hz~ 5 KHz frequency, two alarm outputs: high limit alarm and low limit alarm

Communication: RS485, RS232, MODBUS, HART, PROFIBUS-DP (OPTIONAL)